In industry, steam is an essential energy source but one that is often poorly managed. It is used in many critical processes and accounts for a significant proportion of the overall energy consumption of industrial sites.

Faced with the sustained rise in energy costs, manufacturers must identify concrete levers to improve their energy efficiency and reduce their operating expenses without compromising quality or production continuity.

In this context, steam flow measurement is now an essential strategic tool. Not only does it enable better process control, but it also improves plant safety, provides objective data on actual consumption, and reveals previously invisible losses. It is therefore an indispensable foundation for any energy optimization initiative.

Summarize this article with :

Steam plays a key role in modern industry. It is used as an energy source for a variety of applications, including heating, drying, cooking, sterilization, cleaning, humidification, and as a driving force in certain industrial processes.

Steam systems account for approximately 30% of total energy consumption in the global manufacturing industry. This high percentage demonstrates the dependence of industrial processes on steam as a key source of thermal energy.

In sectors such as agri-food, chemicals, pharmaceuticals, textiles, and energy production, steam is used for both thermal processing and quality control operations. Its ability to transfer heat efficiently during condensation makes it a fluid that is particularly well suited to processes requiring precise and rapid temperature variations.

However, this versatility comes with considerable operational complexity:

This multi-purpose configuration means that detecting losses, overconsumption, or energy drift is particularly difficult without the right measurement tools. Without reliable instrumentation, manufacturers do not have sufficient visibility into the performance of their steam network, which compromises their ability to identify opportunities for optimization and control associated costs.

For several years now, the cost of producing industrial steam has risen sharply.

This increase is due to the approximately 150% rise in gas prices between 2019 and 2022, a fuel widely used for industrial steam production.

It comes amid a backdrop of heightened geopolitical tensions and sustained volatility in energy markets, which is also affecting the prices of fuel oil and other fuels used in industrial boilers.

These developments have a direct impact on production costs and the competitiveness of industrial companies, particularly in sectors that consume large amounts of thermal energy. In this context, controlling steam consumption is no longer solely a matter of technical performance or process optimization, but has become a key economic issue for the sustainability and profitability of industrial activities.

Without reliable measurement, a significant portion of the steam produced can be wasted without being detected. Leaks in the network, faulty steam traps, or excessive condensate can lead to losses that are often invisible but financially significant.

Measuring steam flow allows these deviations to be accurately identified, areas of waste to be located, and the potential savings associated with targeted corrective actions to be objectively quantified.

Poorly controlled steam flow causes temperature and pressure variations within processes. These instabilities can affect the quality of finished products, generate waste, and reduce the overall productivity of facilities.

Real-time measurement allows the steam supply to be adjusted according to the actual needs of the process. This contributes to greater production consistency, more uniform quality, and optimized operational performance.

Steam is a hazardous energy source due to its high pressure and temperature. Continuous flow monitoring allows for rapid detection of anomalies, such as sudden variations or abnormal operating conditions.

It also facilitates the implementation of more effective preventive maintenance by identifying signs of equipment deterioration early on and reducing the risk of incidents or unplanned downtime.

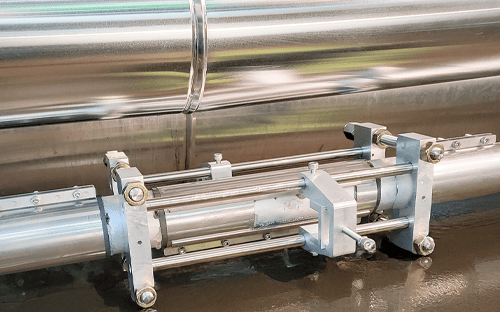

Ultrasonic steam flow measurement is based on non-intrusive technology, suitable for demanding industrial environments. It allows flow to be measured without cutting the piping or interrupting production.

The principle is based on the transmission and reception of ultrasonic waves through the pipe wall. The transit time of the ultrasonic waves is used to accurately calculate the steam flow velocity and then the flow rate.

This technology eliminates all direct contact with the fluid. It thus eliminates constraints related to pressure, temperature, corrosion, or internal mechanical stresses.

Unlike inline flow meters, ultrasonic measurement can measure very low flow rates, even close to zero. It has no dead zone and detects residual consumption or invisible losses.

Installation and commissioning are very quick and do not require any production downtime or modifications to existing piping. Ultrasonic flow measurement is particularly suitable for energy audits and industrial installations in continuous operation.

The FSJ ultrasonic steam flow meter from Fuji Electric is designed to meet the specific requirements of industrial steam networks. It combines reliable measurement, non-intrusive installation, and high robustness.

The FSJ ultrasonic flow meter for steam offers several key advantages for industrial applications:

The FSJ steam flow meter is therefore a key tool for ensuring reliable steam measurement and supporting investment decisions in energy efficiency.

High reliability

Wide measuring range

Loss detection

Reduced maintenance

Continuous monitoring

Measuring steam flow allows for better control of energy consumption, identification of invisible losses, and optimization of industrial processes. It is an essential step in sustainably reducing energy costs and improving overall performance.

Clamp-on ultrasonic steam flow measurement allows installation without interrupting piping or stopping processes. This non-intrusive technology is particularly well suited to industrial sites operating continuously.

An ultrasonic steam flow meter measures without contact with the fluid and can detect very low flow rates without dead zones. Vortex flow meters are less accurate at low flow rates and more sensitive to mechanical stress.

Yes, ultrasonic technology can measure very low steam flow rates, even those close to zero. It highlights residual consumption and continuous losses that often go undetected by traditional technologies.

Yes, clamp-on ultrasonic steam flow meters, such as Fuji Electric's FSJ, are insensitive to water hammer and have no moving parts. They offer high reliability and low maintenance requirements.

The data can be integrated into energy management or monitoring systems via industrial interfaces. It can be used to track consumption, identify deviations, and support investment decisions.