Fuji Electric supports you during the design, supply, installation, commissioning and maintenance of this energy measurement solution.

Our engineers have developed a complete range of energy measurement instruments. These instruments are designed for various applications: liquids, steam, gas, air and biogas.

The aim of these tools is to support you in your energy management process. This is a crucial step for any company concerned with its performance.

Finally, these tools are also designed to help youimprove your competitiveness. They are designed to help you optimize the use of your resources, which can give you a competitive edge.

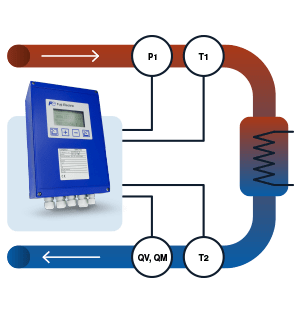

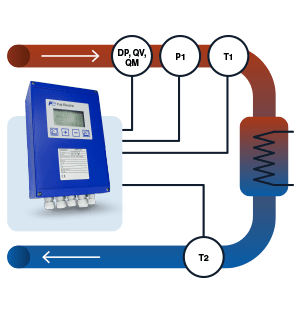

Measurement is performed by pressure transmitters, ultrasonic flowmeters or temperature probes.

Energy meters are used to acquire energy consumption or production data. These devices meet MID and ISO5167 standards and are suitable for commercial transactions.